FlavorActiV

The process of getting top quality coffee, from bean to cup, is long and challenging—but FlavorActiV can help! An industry-led approach to coffee sensory training and calibration has been developed by FlavorActiV, who has been providing sensory training to the beverage industry since 1996.

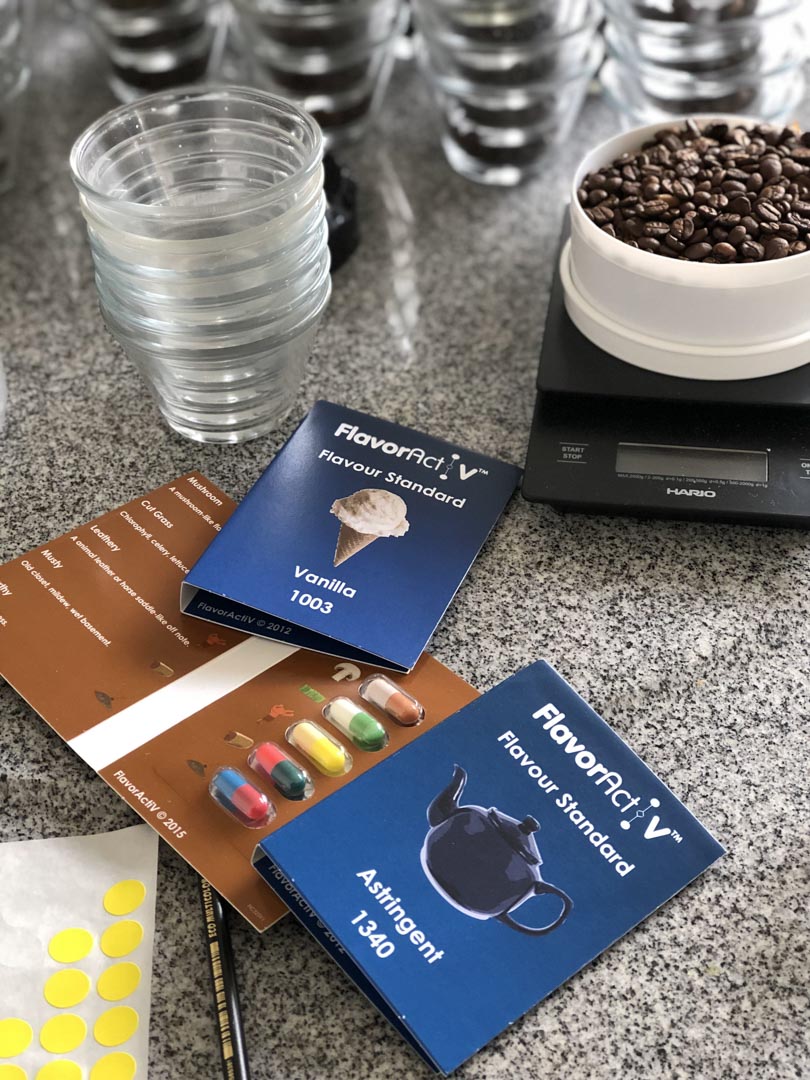

Coffee Flavor Standards Store WCR-SCA / FlavorActiV Name Chart (PDF)Taster Proficiency

Train, Calibrate, Validate, Repeat & Improve

FlavorActiV and Coffee Enterprises are partners in the development of the Coffee Flavor Library, which is specifically designed to train coffee professionals. Since 1996 FlavorActiV has provided sensory training to the beverage industry and is the global leader in the training and monitoring of professional tasting panels. Since 1992 Coffee Enterprises has provided technical services and coffee quality and business consulting to the global coffee industry.

FlavorActiV Pharmaceutical Quality GMP Flavor Reference Standards are used the world over to train beverage sensory panels as they learn how taints, positive and negative flavors can influence quality and brand expectations. Once a panel has undergone its initial training the flavor standards are used to maintain their abilities in double blind Taster Validation testing, supported by FlavorActiV’s proprietary taster software.

FlavorActiV produces its industry leading encapsulated flavors in it’s state-of the-art pharma facility near Liverpool, England.

Globally, the FlavorActiV Taster Validation Scheme (TVS) includes over 2.5 million responses with over 50,000 tasters participating at over 3,000 sites around the world.

Our Three-Step Process

Step 1 – Training. Coffee Enterprises provides comprehensive technical training and educational consulting for coffee quality control, process controls, green coffee sourcing and other coffee product topics.

FlavorActiV offers sensory training and consultancy for sensory panels from structured beverage sensory course to customized train the trainer sessions, including from scratch sensory analysis programs.

Good Sensory Practices (GSP) Training starts companies and sensory panels on the path to improvement. Coffee Enterprise presents this live training seminar at your location. Topics include best practices and pitfalls to avoid when establishing a sensory (cupping & tasting) panel, operating a sensory laboratory for coffee and tea analysis, and upgrading cuppers to sensory specialists. This program is beneficial as a both a functional beginning for small companies and start-up, and also to align experienced coffee cuppers. Training programs may be customized for each companies’ individual needs and may include farm-to cup control points, coffee contract execution, product specifications, quality control laboratory set-up, and managing supply chain risks.

Step 2 – Calibrate to flavor standards. Sensory training with FlavorActiV’s flavor standards to gain familiarity and sensory recognition.

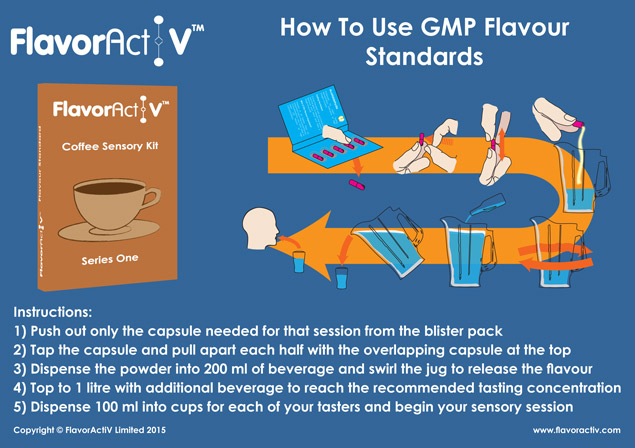

Recommended Dilution

- Beginner Training: 1 capsule to 500 mL (17 fluid ounces) of room temperature water.

- Intermediate Training: 1 capsule to 1 L (34 fluid ounces) of room temperature water.

- Advanced Training: 1 capsule to 300 mL (10 fluid ounces) of hot coffee

Flavor strength may be adjusted: More intense (less liquid) or less intense (more liquid) as needed

Sensory training is a progression of exercises: Beginning with initial flavor identification at high concentrations to gain familiarity by tasting and discussing with other cuppers. Second part is to practice identification without labels, then decrease the intensity of flavors with water or try identification in coffee to gain competence.

Step 3 – Taster Proficiency. FlavorActiV’s Taster Validation Scheme (TVS) is the center of our program. The idea is simple, blind tasting packs of FlavorActiV’s GMP Flavor Standards are sent out to sensory panels around the world at specified intervals, these packs align with a series of tests that challenge flavor identification, whether a sample is in or out of specification, and intensity scoring. Once a panel tasting session is complete the panel leaders will submit results and be presented with a detailed breakdown of individual and panel performance across the entire organization.

Our taster validation program is suited for individuals and sensory panels at companies ranging from micro-roasters to multi-national green coffee trading companies to manage cuppers and sensory panels at different locations and at different stages in the farm-to-cup supply chain. It is flexible enough to allow small companies and individuals to use and calibrate their sensory analysis abilities with other individual users around the world.

FlavorActiV Taster Proficiency

Repeat steps as necessary to increase expertise, maintaining peak performance and accurate flavor identification in a quick and convenient way to ensure beverage quality remains high.

Questions?

Visit our FlavorActiv FAQ.

For ordering please use the online purchasing pages:

FlavorActiV’s global sensory systems team are supported by the United Kingdom based customer support team or email enquiries@flavoractiv.com.

Coffee Enterprises the North American distributor of FlavorActiV products to the coffee industry.

FlavorActiV flavor standards are manufactured by Quay Pharma (www.quaypharma.com) in the United Kingdom.